Industry Disrupting Technology

Pioneering in Car Wash Technology for More Than 25 Years

A New Culture Of Cleanliness

-

Suitable for Petrol Stations

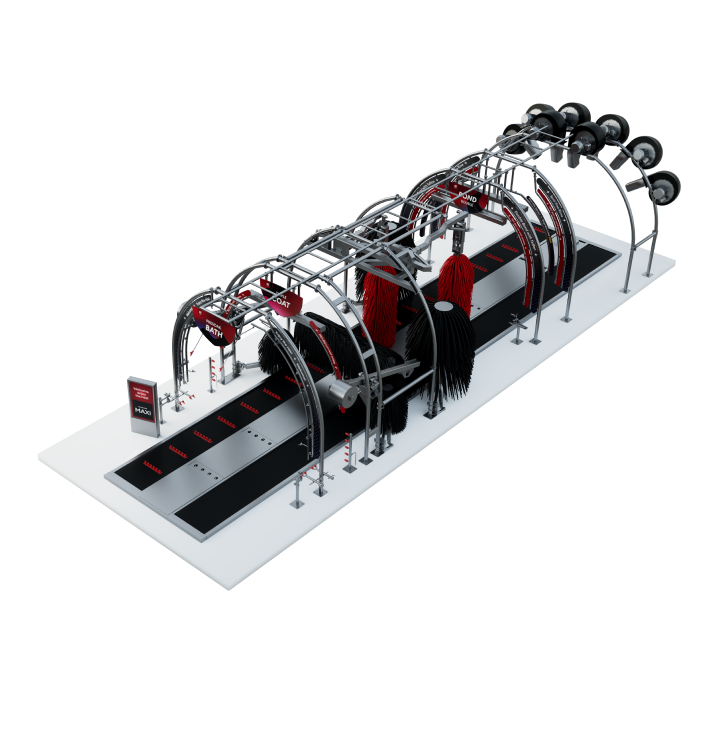

Our PRO40 model of Express Tunnel Car Wash is ideal for compact plots, maximizing capacity within a limited space. This 12-meter tunnel can handle up to 60 cars per hour but fits in the same plot as a rollover car wash, which manages just 8 cars per hour. The Tunnel PRO40 requires a 900 m2 plot and is operated by 3–4 employees. It is a smart option for high-visibility locations where space is at a premium and offers turnover potential of up to €750k+ per year.

-

Welcome Screen

PRO BRO car washes are equipped with information panels and speakers at the front entrance. The welcome screen guides customers and provides opportunities for upselling additional services.

-

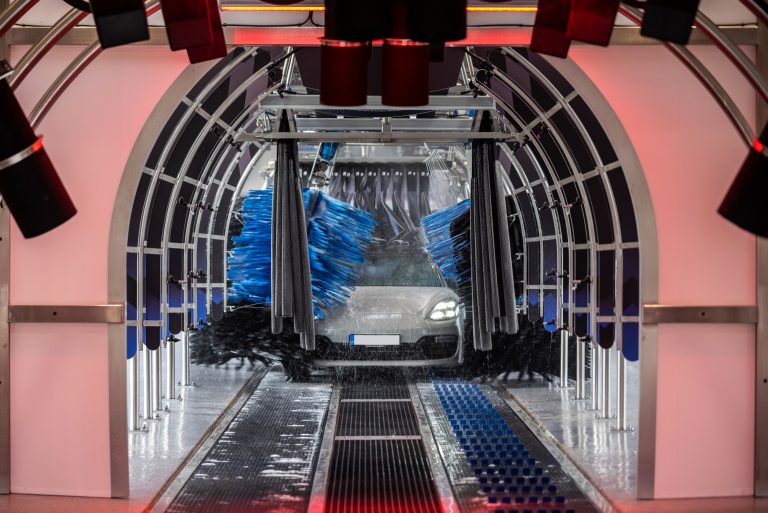

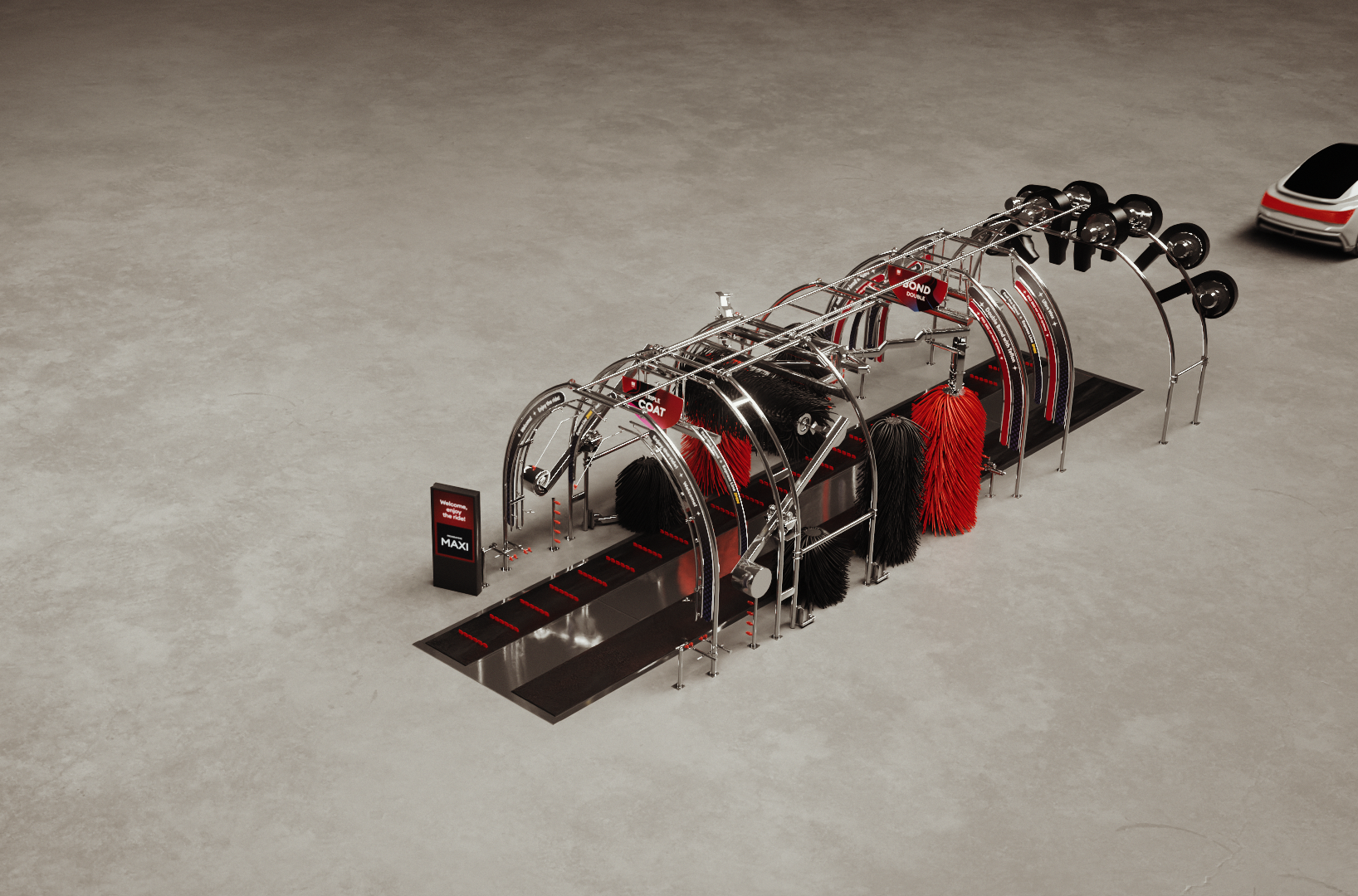

PRO BRO arch

All the cleaning equipment in PRO BRO car washes is located on stainless steel arches. This arrangement guarantees a quick, step-by-step installation process (simply follow the instructions, just like flat-pack furniture). It also ensures easy access to equipment during maintenance and a clutter-free car wash design. In addition, it offers low costs in terms of installation materials and great aesthetic appeal.

-

Underbody wash

Our underbody wash system is mounted to the conveyor frame. As the vehicle moves across the applicator, dirt and debris are removed from its underside. First, the applicator, which is equipped with one of four spray nozzles, soaks the underbody before applying an anti-rust formula. Regular cleaning of the underbody helps prevent rust and corrosion, improve fuel efficiency, enhance appearance and safety, and maintain car value. The housing of the applicator is made of stainless steel. All the plumbing fittings and fixtures come pre-assembled. This makes for an easy, plug-and-play installation process.

-

Advanced anti-collision system

The PRO BRO advanced anti-collision system, installed at the end of our tunnels, has been developed according to our own unique design. It functions remarkably well under heavy-duty wash conditions, including heavy fog, direct sunlight, very high levels of humidity, and strong wind. The system is easy to install and requires only a minimum of maintenance, thanks to a robust protective housing.

-

Drying system

Housed in an ultra-high-durability polymer (UHMW) body, our industrial blower system comes with 10 HP or 15 HP side and top producers mounted on height-adjustable arches or custom frameworks. Pivoting nozzles, a variable-speed motor control system, and other features ensure high performance, easy control, and a wide variety of installation options.

-

Wax zone

In the wax zone, cars are cleaned with a high-pressure spray before wax is applied to the bodywork. The car is then rinsed with water purified by reverse osmosis (osmosis water) that does not leave spots before passing through a drip space where excess water comes off the car. It is then dried. The Wax Zone features a corrosion-resistant stainless steel arch (for larger car washes) or hanging manifolds (for smaller units). Tailored nozzles apply the wax and the osmosis water.

-

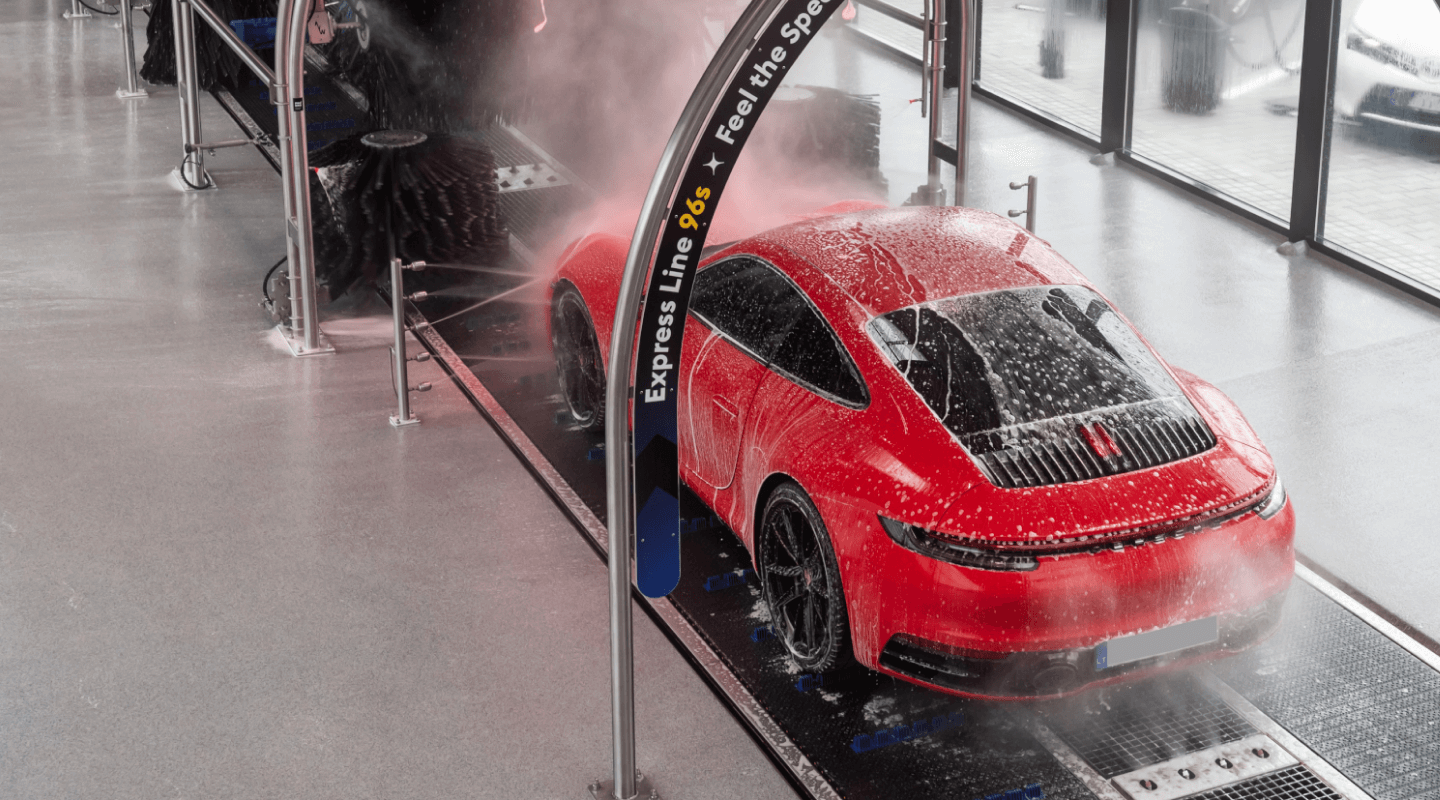

PRO40 Combo

PRO40 Combo is a module that is designed for gas stations and is also suitable for a variety of establishments with limited car wash space. To deliver excellent results with minimum equipment, the module includes mitter, rocker, and wrap-around brushes that complement each other and deliver a thorough wash of the entire vehicle.

-

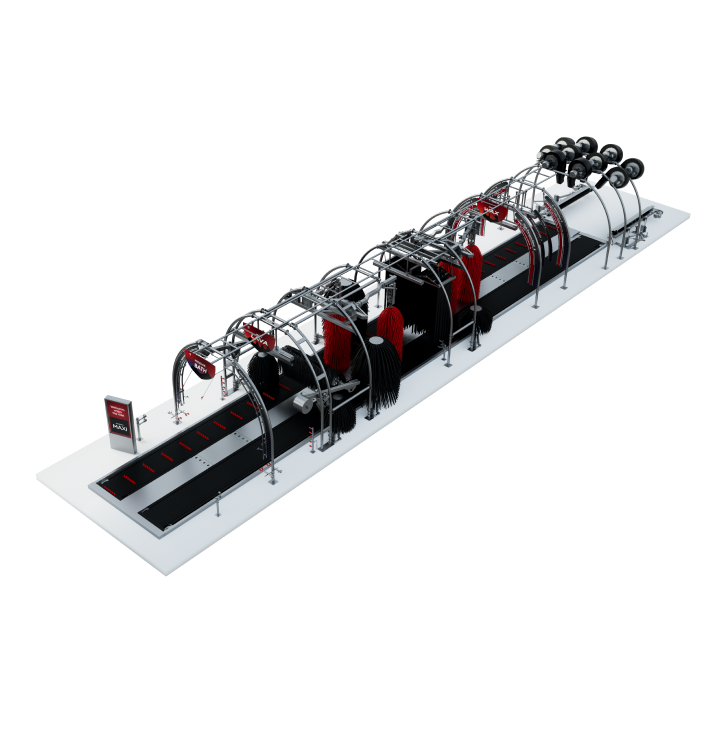

Suitable for Petrol Stations

Our PRO60 model of Express Tunnel Car Wash is ideal for compact plots, maximizing capacity within a limited space. This 15-meter tunnel can handle up to 60 cars per hour but fits in the same plot as a rollover car wash, which manages just 8 cars per hour. The Tunnel PRO60 requires a 900 m2 plot or larger and is operated by 3–4 employees. It is a smart option for high-visibility locations where space is at a premium and offers turnover potential of up to €1 million per year.

-

Welcome screen

PRO BRO car washes are equipped with information panels and speakers at the front entrance. The welcome screen guides customers and provides opportunities for upselling additional services.

-

Dual belt conveyor

Our dual belt conveyors are designed to handle a harsh operating environment that includes the repeated use of strong chemical agents during the wash cycle. The dual belt also provides maximum comfort and safety inside the tunnel. Built to accommodate many different types of vehicles, the conveyor allows for easy loading and stacking, thus ensuring maximum speed of service and optimal use of the available space.

-

PRO BRO arch

All the cleaning equipment in PRO BRO car washes is located on stainless steel arches. This arrangement guarantees a quick, step-by-step installation process (simply follow the instructions, just like flat-pack furniture). It also ensures easy access to equipment during maintenance and a clutter-free car wash design. In addition, it offers low costs in terms of installation materials and great aesthetic appeal.

-

Underbody wash

Our underbody wash system is mounted to the conveyor frame. As the vehicle moves across the applicator, dirt and debris are removed from its underside. First, the applicator, which is equipped with one of four spray nozzles, soaks the underbody before applying an anti-rust formula. Regular cleaning of the underbody helps prevent rust and corrosion, improve fuel efficiency, enhance appearance and safety, and maintain car value. The housing of the applicator is made of stainless steel. All the plumbing fittings and fixtures come pre-assembled. This makes for an easy, plug-and-play installation process.

-

Advanced anti-collision system

The PRO BRO advanced anti-collision system, installed at the end of our tunnels, has been developed according to our own unique design. It functions remarkably well under heavy-duty wash conditions, including heavy fog, direct sunlight, very high levels of humidity, and strong wind. The system is easy to install and requires only a minimum of maintenance, thanks to a robust protective housing.

-

Drying system

Housed in an ultra-high-durability polymer (UHMW) body, our industrial blower system comes with 10 HP or 15 HP side and top producers mounted on height-adjustable arches or custom frameworks. Pivoting nozzles, a variable-speed motor control system, and other features ensure high performance, easy control, and a wide variety of installation options.

-

Wax zone

In the wax zone, cars are cleaned with a high-pressure spray before wax is applied to the bodywork. The car is then rinsed with water purified by reverse osmosis (osmosis water) that does not leave spots before passing through a drip space where excess water comes off the car. It is then dried. The Wax Zone features a corrosion-resistant stainless steel arch (for larger car washes) or hanging manifolds (for smaller units). Tailored nozzles apply the wax and the osmosis water.

-

PRO60 Combo

The PRO60 Combo contains brushes to deliver shorter wash times without sacrificing quality. This module, which includes a top, rocker (standard and XL), and wrap-around brushes, was designed for gas stations and is also suitable for a variety of other establishments with limited space.

-

Welcome screen

PRO BRO car washes are equipped with information panels and speakers at the front entrance. The welcome screen guides customers and provides opportunities for upselling additional services.

-

Dual belt conveyor

Our dual-belt conveyors are designed to handle a harsh operating environment that includes the repeated use of strong chemical agents during the wash cycle. The dual belt also provides maximum comfort and safety inside the tunnel. Built to accommodate many different types of vehicles, the conveyor allows for easy loading and stacking, thus ensuring maximum speed of service and optimal use of the available space.

-

PRO BRO arch

All the cleaning equipment in PRO BRO car washes is located on stainless steel arches. This arrangement guarantees a quick, step-by-step installation process (simply follow the instructions, just like flat-pack furniture). It also ensures easy access to equipment during maintenance and a clutter-free car wash design. In addition, it offers low costs in terms of installation materials and great aesthetic appeal.

-

Underbody wash

Our underbody wash system is mounted to the conveyor frame. As the vehicle moves across the applicator, dirt and debris are removed from its underside. First, the applicator, which is equipped with one of four spray nozzles, soaks the underbody before applying an anti-rust formula. Regular cleaning of the underbody helps prevent rust and corrosion, improve fuel efficiency, enhance appearance and safety, and maintain car value. The housing of the applicator is made of stainless steel. All the plumbing fittings and fixtures come pre-assembled. This makes for an easy, plug-and-play installation process.

-

Advanced anti-collision system

The PRO BRO advanced anti-collision system, installed at the end of our tunnels, has been developed according to our own unique design. It functions remarkably well under heavy-duty wash conditions, including heavy fog, direct sunlight, very high levels of humidity, and strong wind. The system is easy to install and requires only a minimum of maintenance, thanks to a robust protective housing.

-

Drying system

Housed in an ultra-high-durability polymer (UHMW) body, our industrial blower system comes with 10 HP or 15 HP side and top producers mounted on height-adjustable arches or custom frameworks. Pivoting nozzles, a variable-speed motor control system, and other features ensure high performance, easy control, and a wide variety of installation options.

-

Wax zone

In the wax zone, cars are cleaned with a high-pressure spray before wax is applied to the bodywork. The car is then rinsed with water purified by reverse osmosis (osmosis water) that does not leave spots before passing through a drip space where excess water comes off the car. It is then dried. The Wax Zone features a corrosion-resistant stainless steel arch (for larger car washes) or hanging manifolds (for smaller units). Tailored nozzles apply the wax and the osmosis water.

-

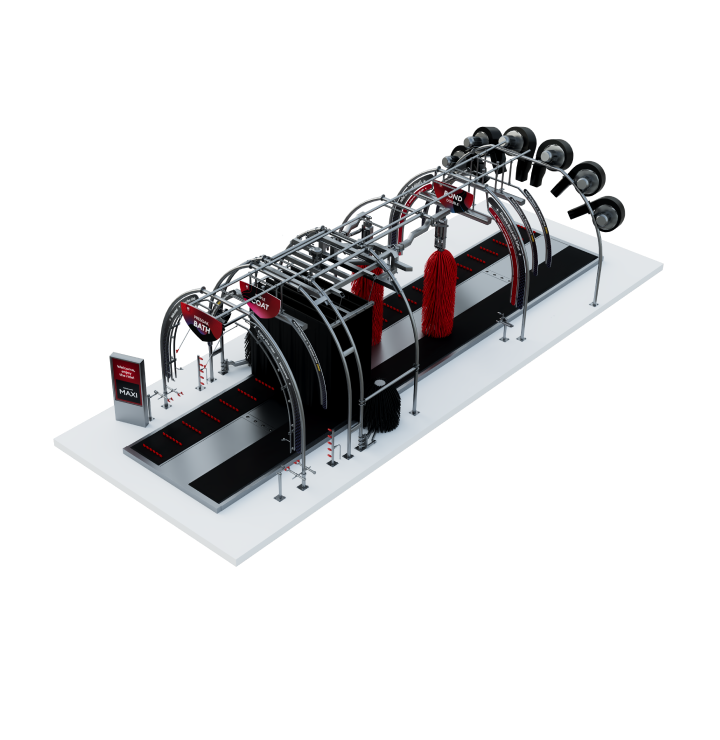

PRO120 Combo

The PRO120 Combo contains brushes and is intended for larger stand-alone car washes, enabling the shortest wash cycles without compromising on quality. The module includes top, rocker (standard and XL), wrap-around, mitter, and contour brushes.

-

Tire glossing applicator

To ensure the perfect level of tire gloss, our tire glossing system features high-efficiency, leg-mounted bristle applicators, shielded nozzles for extra consistency, and a rotating applicator brush.

-

Welcome screen

PRO BRO car washes are equipped with information panels and speakers at the front entrance. The welcome screen guides customers and provides opportunities for upselling additional services.

-

Dual belt conveyor

Our dual-belt conveyors are designed to handle a harsh operating environment that includes the repeated use of strong chemical agents during the wash cycle. The dual belt also provides maximum comfort and safety inside the tunnel. Built to accommodate many different types of vehicles, the conveyor allows for easy loading and stacking, thus ensuring maximum speed of service and optimal use of the available space.

-

PRO BRO arch

All the cleaning equipment in PRO BRO car washes is located on stainless steel arches. This arrangement guarantees a quick, step-by-step installation process (simply follow the instructions, just like flat-pack furniture). It also ensures easy access to equipment during maintenance and a clutter-free car wash design. In addition, it offers low costs in terms of installation materials and great aesthetic appeal.

-

Underbody wash

Our underbody wash system is mounted to the conveyor frame. As the vehicle moves across the applicator, dirt and debris are removed from its underside. First, the applicator, which is equipped with one of four spray nozzles, soaks the underbody before applying an anti-rust formula. Regular cleaning of the underbody helps prevent rust and corrosion, improve fuel efficiency, enhance appearance and safety, and maintain car value. The housing of the applicator is made of stainless steel. All the plumbing fittings and fixtures come pre-assembled. This makes for an easy, plug-and-play installation process.

-

Advanced anti-collision system

The PRO BRO advanced anti-collision system, installed at the end of our tunnels, has been developed according to our own unique design. It functions remarkably well under heavy-duty wash conditions, including heavy fog, direct sunlight, very high levels of humidity, and strong wind. The system is easy to install and requires only a minimum of maintenance, thanks to a robust protective housing.

-

Drying system

Housed in an ultra-high-durability polymer (UHMW) body, our industrial blower system comes with 10 HP or 15 HP side and top producers mounted on height-adjustable arches or custom frameworks. Pivoting nozzles, a variable-speed motor control system, and other features ensure high performance, easy control, and a wide variety of installation options.

-

Wax zone

In the wax zone, cars are cleaned with a high-pressure spray before wax is applied to the bodywork. The car is then rinsed with water purified by reverse osmosis (osmosis water) that does not leave spots before passing through a drip space where excess water comes off the car. It is then dried. The Wax Zone features a corrosion-resistant stainless steel arch (for larger car washes) or hanging manifolds (for smaller units). Tailored nozzles apply the wax and the osmosis water.

-

PRO180 Combo

The PRO180 Combo contains brushes and is intended for larger stand-alone car washes, enabling the shortest wash cycles without compromising on quality. The module includes top, rocker (standard and XL), wrap-around, mitter, and contour brushes.

-

Tire glossing applicator

To ensure the perfect level of tire gloss, our tire glossing system features high-efficiency, leg-mounted bristle applicators, shielded nozzles for extra consistency, and a rotating applicator brush.

tour of the tunnel

-

PRO BRO: Disrupting Technology

180 clean cars in an hour

The car is washed in 2 minutes

Up to ten times more volume than the standard ROI -

Subscription model: Unlimited Wash

This car wash solution is designed for a subscription model

The car is always effortlessly clean

Different B2B approaches -

Phone application/WEB

You don’t even need to open the window

Time-saving, comfortable, and easy to use -

Quality vs. profit adjustment (87 CSI)

The business model is adjustable to the circumstances

-

Concept of cleanliness

Customer experience through the senses

-

Additional ecosystem of services

Full service delivery and client satisfaction

-

Color, smell, and light effects

Customer experience through sense and customization possibilities

-

High Automation Level

High speed, low labor costs, high service quality, and low human error possibility

-

Special Conveyor Belt

Safe and fast, it has a special safety function

Safe for your wheels

Safe four-wheel system: easy to load, no scratching of alloy wheels, low accident rate -

Unique anticollision function

Time and cost savings, low labor costs, high service efficiency, and low error possibility

Our product is designed to work without a prewash zone -

License plate recognition system

No queues, low labor costs, an effective process, customer data

-

Fast moving gates

Time savings, process efficiency, and safety

-

Unique tire shiner technology

Perfection to the last

Unique selling point, competitive advantage, better ROI, customer satisfaction -

Self-loading on conveyer processes

Upsell possibility, safety feeling, low labor costs, high service efficiency

-

Water Recycling System

Implementing a state-of-the-art water recycling system means reclaiming up to 90% of the water used in our processes.

Reducing water consumption and conserving this precious resource. -

PRO BRO Arches

PRO BRO car washes have one-of-a-kind stainless-steel arches that vehicles move through during the wash cycle.

It has an extremely long life cycle and is rust-free, ensuring long-term sustainability. -

No Pre-wash zone

Our solution does not require a prewash zone; there are fewer chemicals in the washing process.

-

Enhancing Process Efficiency

Minimizing chemical usage

Advanced technologies to measure car dirtiness and optimize chemical dosing for minimal environmental impact. -

Innovative Filtration

Filtering car waste and water with specialized filters effectively captures oil products and contaminants.

Disposal adheres to stringent environmental standards. -

Energy-Efficient Practices

Exclusive use of energy-saving LED lights throughout our facilities.

Lowering energy consumption and decreasing our carbon footprint.

What is best in your case

-

12-15 meters RenovationWith PRO BRO, you can retrofit your existing gas station or other premises, turning them into a modern car wash that adds extra value to your existing business. Cutting-edge technology, smart design, and easy stacking of vehicles in the express car wash ensure a high return on investment, world-class performance, and exceptional speed of service. The PRO BRO model can process up to 60 vehicles per hour, which is up to 10x more than most rollover car washes.

12-15 meters RenovationWith PRO BRO, you can retrofit your existing gas station or other premises, turning them into a modern car wash that adds extra value to your existing business. Cutting-edge technology, smart design, and easy stacking of vehicles in the express car wash ensure a high return on investment, world-class performance, and exceptional speed of service. The PRO BRO model can process up to 60 vehicles per hour, which is up to 10x more than most rollover car washes. -

26-36 meters InnovationIf you don’t have any vacant or otherwise suitable premises that could be retrofitted, a new PRO BRO car wash can be built from the ground up, including equipment and the building itself. Cutting-edge technology, smart design, and easy stacking of vehicles in the express car wash ensure a high return on investment, world-class performance, and exceptional speed of service. PRO BRO car washes have a market-leading volume of up to 180 vehicles per hour.

26-36 meters InnovationIf you don’t have any vacant or otherwise suitable premises that could be retrofitted, a new PRO BRO car wash can be built from the ground up, including equipment and the building itself. Cutting-edge technology, smart design, and easy stacking of vehicles in the express car wash ensure a high return on investment, world-class performance, and exceptional speed of service. PRO BRO car washes have a market-leading volume of up to 180 vehicles per hour.

Leadership that makes you shine

PRO BRO Car Wash Systems primary focus is on cutting-edge technologies, innovative car wash equipment, and operational solutions for the most successful business operations.

In 1998, under the name Švaros Broliai (or Brothers of Cleanliness in English), we developed a successful car wash business model. And we have been expanding and evolving ever since. By 2021, we were offering three distinct services: car cleaning, premises cleaning, and the production of car wash cleaning equipment and materials. And we had outgrown our previous brand and business setup. We established the PRO BRO Group, an international holding management company, to help us refine our activities and set independent goals for each of our services. With this structure established and with our decades of experience and knowledge, we are now ready to grow our presence in new markets.

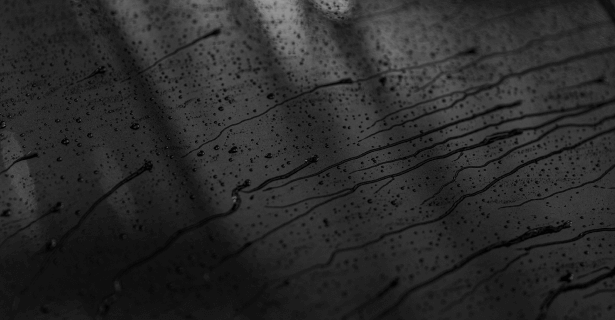

The planet & Sustainability

We place a high value on doing business in a socially responsible and ethical manner. We believe that a car wash cleaning service that is both reliable and convenient should be as clean as possible and support our communities. Our future vision is striving for maximum sustainability and dedicating eco-friendly practices and responsible operations. Together, we drive change, ensuring a cleaner, brighter tomorrow for generations to come.

-

Water Recycling System

Implementing a state-of-the-art water recycling system means reclaiming up to 90% of the water used in our processes. Reducing water consumption and conserving this precious resource.

-

PRO BRO Arches

PRO BRO car washes have one-of-a-kind stainless-steel arches that vehicles move through during the wash cycle. It has an extremely long life cycle and is rust-free, ensuring long-term sustainability.

-

No Pre-wash zone

Our solution does not require a prewash zone; there are fewer chemicals in the washing process.

-

Enhancing Process Efficiency

Minimizing chemical usage Advanced technologies to measure car dirtiness and optimize chemical dosing for minimal environmental impact.

-

Innovative Filtration

Filtering car waste and water with specialized filters effectively captures oil products and contaminants. Disposal adheres to stringent environmental standards.

-

Energy-Efficient Practices

Exclusive use of energy-saving LED lights throughout our facilities. Lowering energy consumption and decreasing our carbon footprint.